The key to wine bottle protection and stopping leaks

Like any other food or beverage product, people buy wine to enjoy, but many also purchase it as a long-term investment or to add to a private collection. As a wine importer, you want to give all your customers the high-value, high quality product they expect, every time.

Wine is carefully crafted and stored at the winery to ensure the best possible quality. But both the quality and value of your wine may drop if the bottles are not protected properly during transportation and storage. Let’s take a look at the risks your wine can face and how you can ensure the best wine bottle protection to maintain its shelf life and value.

What is wine bottle protection?

Wine protection refers to different methods and techniques used to protect wine from spoilage or damage. You need to be aware of the dangers of light, humidity, temperature, oxidation and vibrations and take the steps to safeguard your wines.

How does wine get spoiled?

Good first impressions are crucial for sales. So the condition of the label on your bottle is a primary signal to them about the contents. It’s the face of your brand, and it's important to protect it from damage.

Accidents can happen, and any label could be torn, scuffed, or stained, but as a consumer, you wouldn’t pick up a bottle from the shelf with a damaged label. One study found that 58% of customers said damaged packaging ‘would deter them from buying a product.’

It just doesn’t feel right to hand over your money for a disfigured product when there are plenty of other options on the shelves in perfect condition.

Just one bad label on a bottle at the front of the shelf can discourage customers from buying any of the good bottles behind it. Also, a damaged label can make loyal customers think the quality of your wine is getting worse and avoid buying or recommending your brand in the future. This can harm your sales and reputation for quality, which is difficult to build.

But is the effect of a damaged label purely psychological? Logically, we might tell ourselves that a label doesn't have any reflection on the quality of what’s in the bottle. But is that really true? Damaged labels can be a consequence of container rain, and this can also affect the quality of the wine.

What is container rain?

Container rain, more commonly known as condensation, and can happen when the humidity level in a container is above optimum. This occurs due to the temperature differences between the air outside the container and the air inside, which causes moisture in the air to condense on the cooler surfaces of the container.

This moisture can then literally rain down on your wine boxes, spoiling the labels. It often happens when a shipment moves from a colder climate to a warmer one, or because of temperature changes from day to night.

When cork comes into contact with humidity, it can expand or contract, causing it to lose its airtight seal. This can lead to leakage or oxidation and spoilage of the wine, resulting in off-flavors and aromas.

Container rain, without wine bottle protection, can cause the wine to become damp or humid, which can encourage the growth of mold or bacteria. Again, this can result in spoilage or off-flavors in the wine.

How do you prevent container rain?

To protect your precious wine, freight forwarders specializing in beverages such as Hillebrand Gori can supply you with interior container liners. Hillebrand Gori’s insulation liner has a membrane ceiling that allows humidity to escape, keeping the rain away from your wine, preventing damage to their labels, and ensuring maximum wine bottle protection.

What causes wine bottle leakage?

If a label has been stained by a leak, it’s also a good sign the wine in that bottle or another in the batch has been compromised.

It’s obvious that sometimes wine bottles can leak in transit, but we asked ourselves, ‘Is the problem global wine transportation or is it something else’.

Our study revealed that on the rare occasion a wine bottle did leak, it was due to the seal and closure failing. Leakage can be caused by several factors, including improper cork selection. This can damage labels and cartons and add cost, whilst diminishing brand integrity.

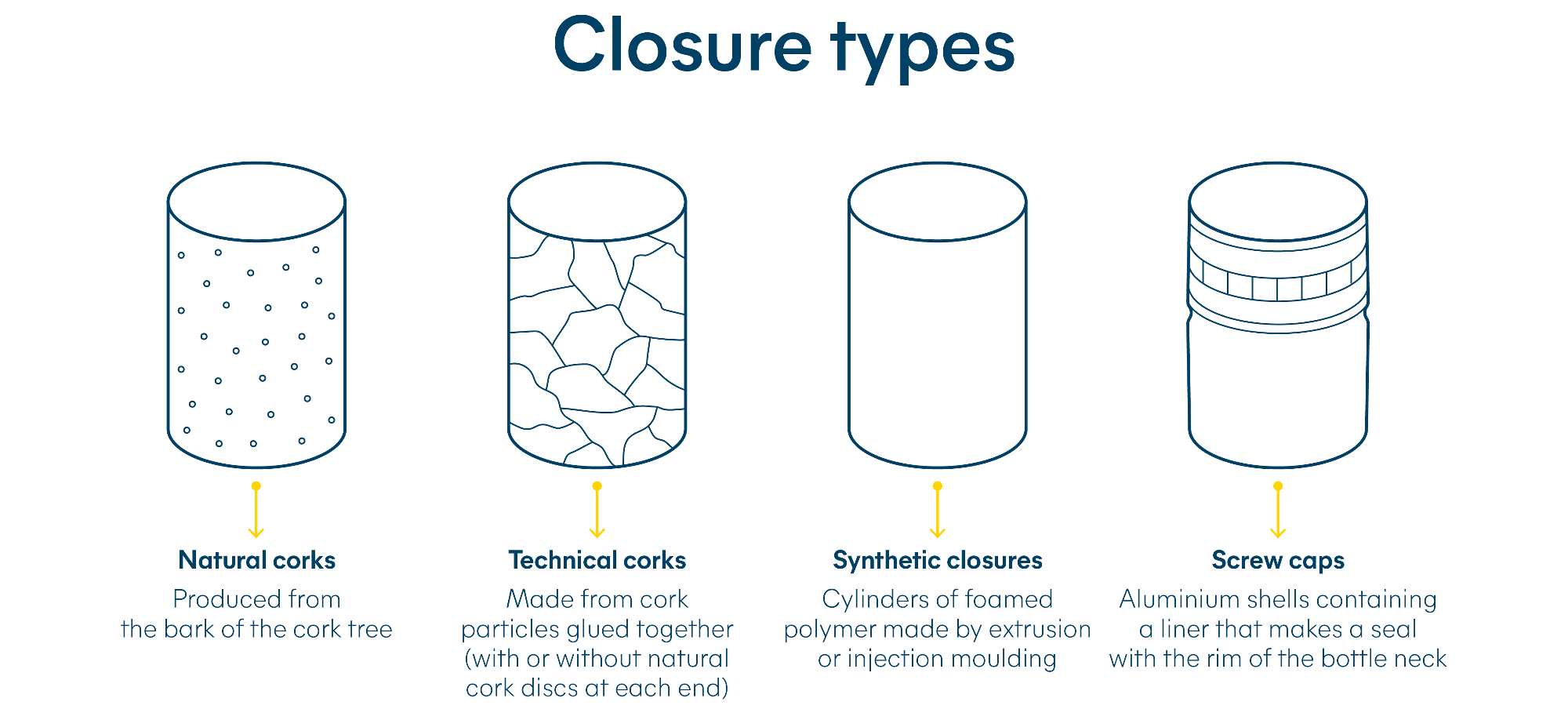

Closure types

What causes wine bottle seal failure?

Excessive pressure and bottle faults are the main sources of leakage according to our research.

When filling the bottle, consider the temperature, closure length, and headspace. Pressure inside the bottle neck is important for cork and synthetic closures.

The bore profile also impacts the sealing of inserted closures, while screw caps rely on the gasket's integrity and a smooth bottle neck rim. Low humidity can dry out the cork and cause it to shrink, while sudden temperature changes can put pressure on the seal and push the cork out.

Packing the bottle

It’s nearly impossible to tell if a cork has an internal flaw which may cause it to fail. The quality of material and the upright position of the bottle for a time after filling (cork recovery) should create an effective seal. More obviously, physical damage from denting due to mishandling, greatly compromises seal integrity.

How can temperature affect wine?

On top of damaging the seal, extreme temperature changes along the transit route can cause deterioration through thermal shock. This changes the chemical structure of the wine and permanently spoils its flavor and aroma.

Prolonged heat makes wine age faster, causing a loss of color and acidity and replacing the freshness and fruity aromas for subtle flavors with a sour taste.

Temperature changes can force the wine to expand and contract, which can affect the tightness of the cork and allow oxygen to enter the bottle. This can result in oxidation, which can cause the wine to develop off-flavors and aromas, such as a "corked" or "musty" taste.

In addition, thermal shock can lead to other physical changes in the wine, such as cloudiness or sedimentation. These changes can affect the wine's appearance and texture, and may also impact its overall quality.

Temperatures that are too cold can also affect your wine’s quality. Between +5°C and 10°C (41°F and 50°F), the wine can become flat and dull, losing its fruitiness and complexity. Itt can cause sedimentation and the tartaric acid might crystallize. This can result in a cloudy appearance and a gritty texture. In extreme cold, between -7ºC and -10ºC (19.4°F and 14°F), wine can freeze. As it freezes it expands, and can break the glass or force the cork out of the bottle, causing oxidation.

How do you ensure wine bottle protection against thermal shocks, humidity and container rain?

Research shows that during shipment, wine can typically experience temperatures of over 30ºC during half its journey and extremes can fluctuate between 4 and 44°C. However, a wine’s unique qualities are best preserved at a temperature range of between +10°C and 20°C (+50°F and 68°F). This range should be maintained all along the cargo journey.

A freight forwarder like Hillebrand Gori can offer a variety of solutions to help you move your wine and protect it from thermal risks.

We can use highly accurate climate predictions to analyze your planned route and identify any potential risks in advance.

With our refrigerated containers, you can be certain that your shipment will be kept dry under to-the-degree temperature control and enjoy our superior wine bottle protection throughout its journey.

Another cost-effective and sustainable option is Hillebrand Gori insulation liners for pallets and containers. The in-house designed liners are the only ones with a breathable membrane that allows humidity to escape, stabilizing the humidity level around 70%. They also protect your wine by eliminating 80% to 90% of thermal shocks. Additionally, Hillebrand Gori insulation liners will protect your beverages from bad smells and cross contamination, helping to maintain the quality of your wine.

Thanks to our groupage service, your wine will only be packed with other beverages, so you know it will be even safer from unwanted odors and tainting by other goods. Take a look at our website pages for more information on international transport services for wine bottles in full loads or less than full loads.

Moving your wine while maintaining its quality and preventing premature aging doesn’t have to be a complex challenge. Beverage logistics specialists like Hillebrand Gori can help you carefully plan and execute your shipments.

Our extensive experience means we understand potential risks like humidity, and extreme temperatures and know how to prevent them. You can count on us to make sure your wines get to their destination in perfect condition. Contact us today to discuss your specific needs and ask for a customized quote.

How can we help your business grow?

.png?sfvrsn=59cab711_1)